In the global of present-day production, injection molding stands as a cornerstone, allowing the manufacturing of intricate components with precision and performance. Lemal Production, a respected name inside the enterprise, showcases its understanding of injection molding on its internet site www.kemalmfg.com. In this text. We will delve into Kemal Manufacturing's injection molding talents, with particular attention on the category of injection molding molds, to apprehend how they have mastered the art www.kemalmfg.comork of precision in this subject.

Injection Molding Capabilities:

Kemal production's injection molding capabilities are a testament to their dedication to handing over high-quality, exactly engineered additives. Let's explore these capabilities in detail:

1. Materials Choice:

The system begins with the choice of substances, an essential component of injection molding. Kemal manufacturing offers an extensive variety of materials, together with diverse thermoplastics and thermosetting plastics, as well as metals. The selection of material relies upon the unique necessities of the assignment, consisting of elements like electricity, sturdiness, warmness resistance, and chemical resistance.

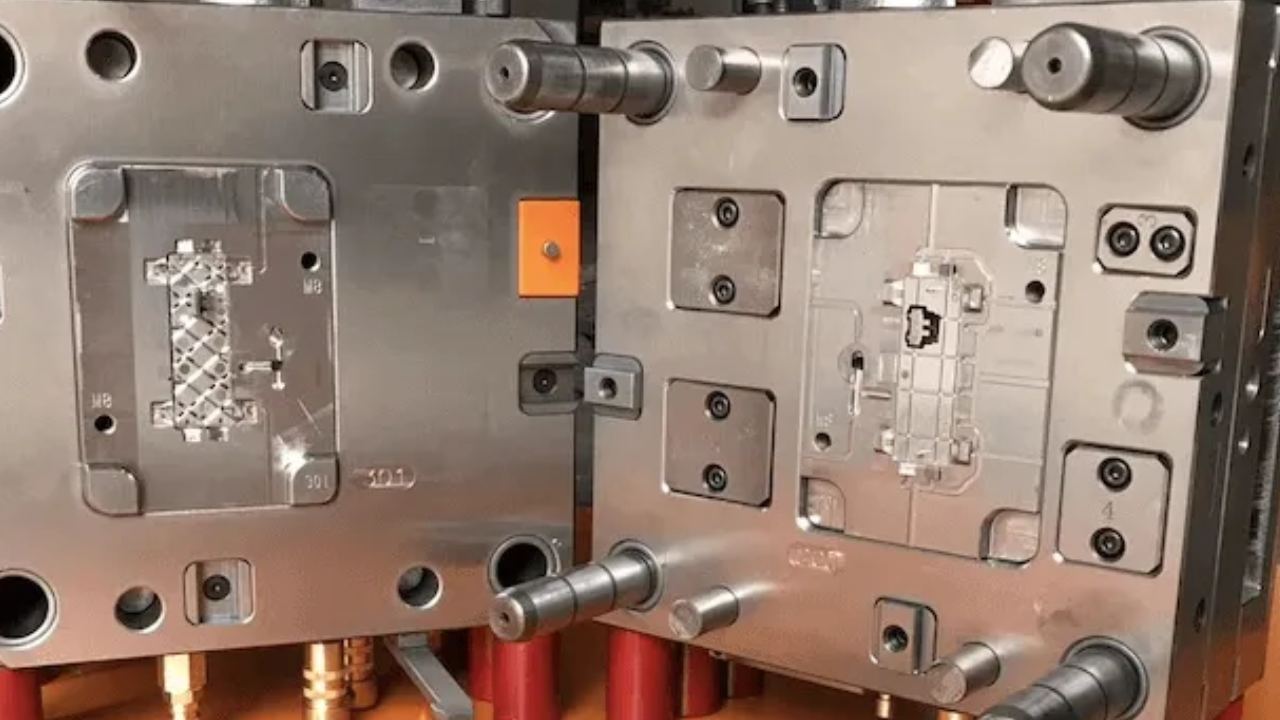

2. Mold Design:

The heart of any successful injection molding technique is a properly designed mold. Kemal manufacturing makes use of superior layout software programs and tools to create molds tailored to the consumer's specifications. These molds are precision-engineered to make certain the very last additives meet the preferred form, length, and best standards.

3. Mold Material:

After the mould layout segment, the actual mildew is fabricated. Kemal production's modern-day centers are prepared with superior equipment to produce molds with precision. These molds are designed to withstand the pressures and temperatures of the injection molding method, ensuring consistency and reliability all through manufacturing.

4. Injection Molding Process:

The heart of the operation is the injection molding technique itself. It begins with the injection device heating the chosen cloth to a molten nation. The molten material is then injected into the mould cavity underneath pressure, wherein it takes the form of the mould. The cooling section follows, allowing the material to solidify and take the favored shape.

5. Exceptional Guarantee:

Quality is a top precedence for Kemal manufacturing. They adhere to stringent control measures, ensuring that every injection molded component meets the consumer's exact specifications. This dedication to pleasant extends to industries with the strictest standards, together with the automotive and scientific sectors. Customers can believe that their components could be of the very best high quality.

Classification of Injection Molding Molds:

One of the key factors that contribute to Kemal production's injection molding fulfillment is their mastery of various types of injection molding molds. Injection molds may be labeled into numerous categories primarily based on various parameters. Right here are a few common classifications:

Via Characteristic:

These are used for creating prototypes and are regularly made from much less high-priced materials. Those are designed for excessive-extent manufacturing and are constructed with greater long-lasting materials to face up to the damage and tear of continuous use.

By using the Runner Machine:

In these molds, the cloth solidifies inside the runner gadget, resulting in a waste fabric that should be eliminated and recycled. These molds have a heated runner system, which guarantees that the material stays in a molten state, minimizing waste and enhancing efficiency.

Through component Complexity:

Those molds are used for producing truthful, single-element additives. Designed for complicated elements, those molds have more complicated systems and can contain a couple of cavities.

With the Aid of Mold Cavity Number:

Those molds create one component in step with the cycle and are ideal for small manufacturing runs. These molds produce more than one part in a single cycle, notably increasing production performance.

By Using Material:

Those are commonly used for speedy prototyping and quick production runs. Those are durable and appropriate for high-extent manufacturing.

Kemal Manufacturing's proficiency lies in its capacity to select the right kind of mildew for every assignment, ensuring green manufacturing that meets the purchaser's specs and volume requirements.

Conclusion

Kemal Manufacturing's injection molding capabilities, coupled with their information in classifying and making use of different varieties of injection molding molds, show their dedication to precision and excellence. As the manufacturing enterprise continues to adapt, injection molding remains a key technique in the manufacturing of elaborate additives. Kemal production's determination to be satisfactory.